Solutions & Technologies for Pipeline

Installation

We deliver projects with Scandinavian quality from start to finish. Our certified welders ensure top-notch craftsmanship, and we proudly offer competitive salaries to skilled professionals who become part of our welcoming team.

- 10+

- Projects

- 13+

- Employees

- 192+

- KMs of Pipelines

Technologies forPipeline

InstallationWe deliver projects with Scandinavian quality from start to finish. Our certified welders ensure top-notch craftsmanship, and we proudly offer competitive salaries to skilled professionals who become part of our welcoming team.

About Us

At Pinstall, we provide expert pipeline installation services, customized to meet the unique needs of each client.

Our certified welders specialize in TIG, MMA, and MIG/MAG processes, with extensive experience in X-ray and ultrasound standards. We consistently deliver efficient, professional results, no matter the challenge.

Our Projects

Coop Installation

In 2021, we completed a large-scale piping project at Coop Lager in Eskilstuna. This included over 11 km of stainless steel glycol pipes (DN25–300) and black steel (P235GH) ammonia lines connecting compressors, heat exchangers, pumps, and tanks. We installed 51 cooling and 5 freezing units, with the main line routed along the roof and internal connections made beneath the ceiling. All welding met X-ray and visual inspection standards.

Atria Sweden AB

In 2021, we installed a comprehensive cooling and freezing system for Atria Sweden AB. The project included routing of pipelines along the roof and beneath the ceiling, installation and connection of 52 cooling and freezing units, and integration of the control room. We used stainless and black steel (P235GH) for ammonia and glycol systems, integrating them with existing lines. The project was completed on a tight schedule with full compliance to safety and quality standards.

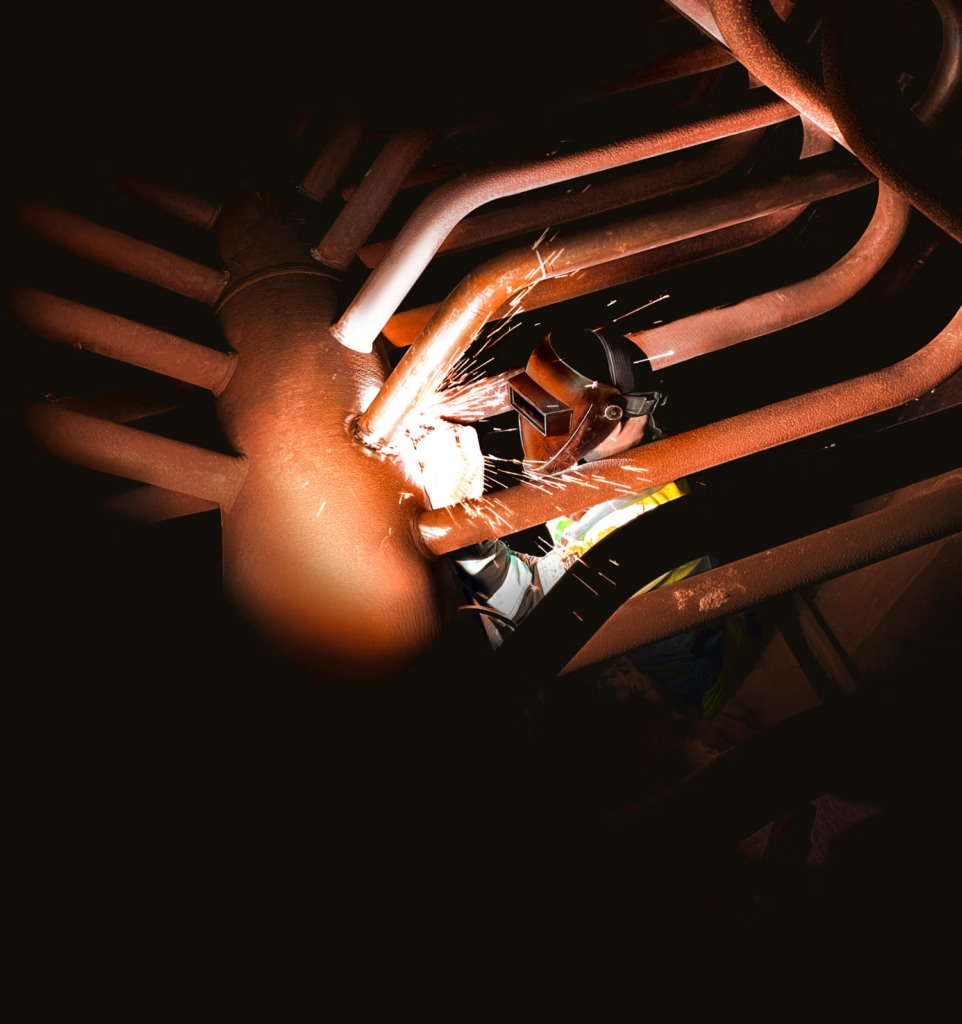

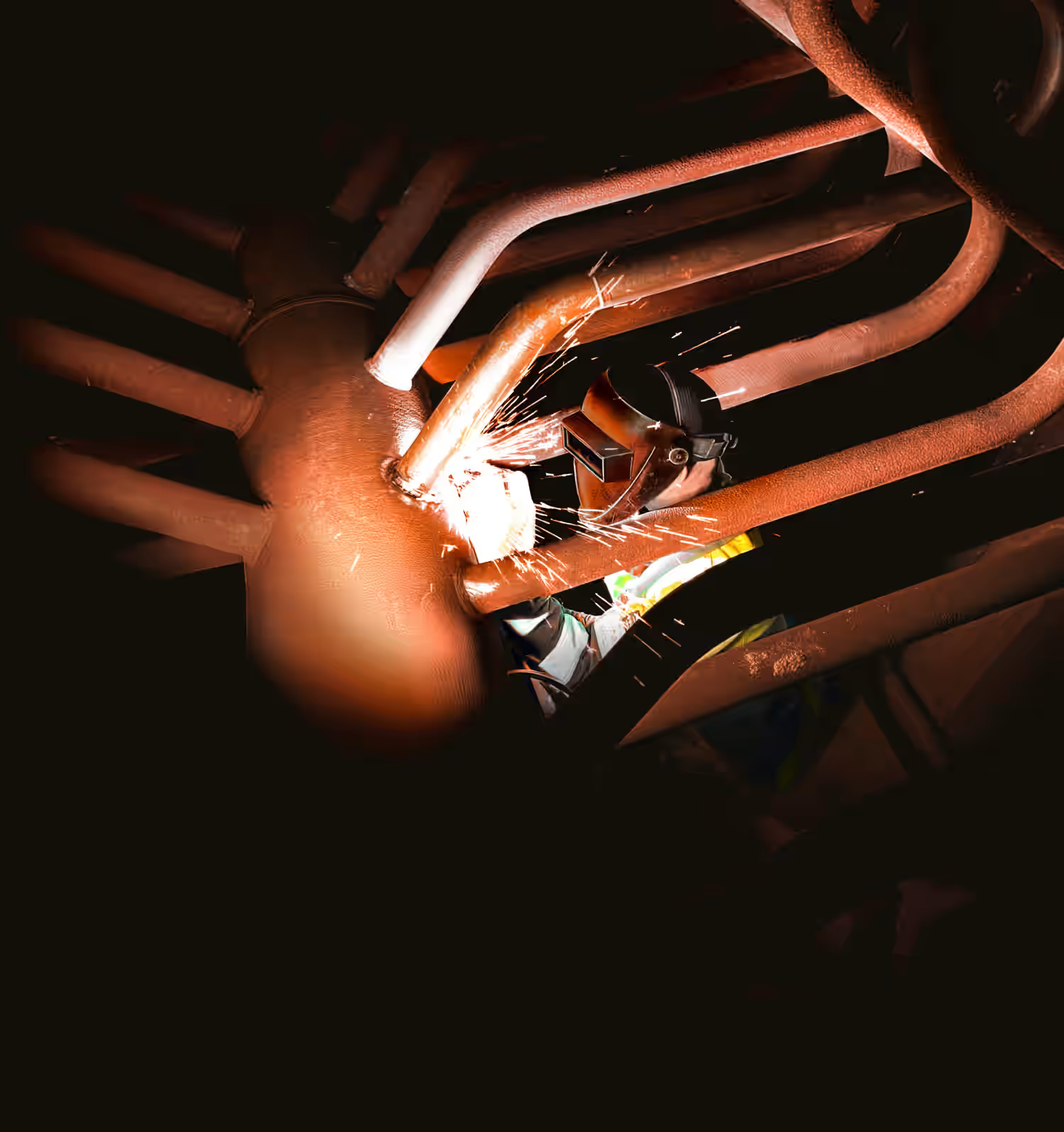

Boiler Top Section Replacement

At an industrial site in Sweden, we carried out the replacement of the upper section of a boiler using chrome-molybdenum pipes. The project involved 110 butt weld joints, each subjected to X-ray inspection. A key challenge was the precise fitting and welding of pipes in very tight and hard-to-reach spaces with minimal clearance between elements. Despite the difficult conditions, the two-week project was successfully completed by a six-person team, meeting all quality, safety, and timeline requirements.

Large-Diameter Pipe Welding

Our team carried out welding work on pipes ranging from 400–1000 mm in diameter using carbon (black) steel and duplex stainless steel. For black steel, TIG welding was used for the root pass and manual arc welding for the fill. For duplex steel, both root and fill passes were completed using electrode welding. 10% of welds underwent X-ray inspection. All work was performed in accordance with the technical requirements for welding complex metals and strict quality control standards.

Piping Installation and Welding

We completed the installation and welding of piping systems at the DAGAB facility in Landskrona, Sweden, including stainless steel glycol lines and steel ammonia pipes in the control room. The project featured insulated pipes and coolers ranging from 25 to 300 mm in diameter, along with necessary hangers and supports. 5% of welds were X-ray inspected to ensure quality. All work met strict safety and quality standards for ammonia and glycol systems.

IKEA Food Supply AG

At the IKEA FOOD SUPPLY AG facility in Hyllinge, we completed the full piping installation and welding for two roof levels and the control room. The project included insulated rooftop pipes for glycol and ammonia systems, connections to heat exchangers, tanks, compressors, and valve groups, plus over 12 km of stainless (Ø25–300 mm) and black steel piping. Welding was performed to technical specs, with 10% of welds per welder X-ray inspected. All work met strict safety, quality, and deadline requirements.

Frozen Food Plant Capacity Upgrade

We expanded capacity at a frozen food production site, meeting strict hygienic and technical standards. The project included TIG-welded ammonia pipelines from black and stainless steel (Ø25–250 mm), with 10% of welds X-ray inspected. Piping was installed with a slope for ammonia drainage and prepared for 100 mm of foam insulation in metal cladding. Connections to existing lines were made in limited-access areas. All work complied with food industry safety, quality, and hygiene requirements.

Industrial Boiler Repair and Welding

We provide expert repair and welding services for industrial boilers, with precise fitting of replacement sections and full technical accuracy in screen tube and joint welding. Our procedures include preheating to maintain material integrity and the use of advanced materials like chromium-molybdenum alloys, Inconel, and duplex stainless steel. Both TIG and electrode welding methods are employed as needed. All welds undergo 100% X-ray inspection to ensure top-tier quality and safety.

Cooling System in Container

We assembled, installed, and connected the piping system for a control room of a glycol cooling system housed in a container. The project was carried out within a highly confined space, requiring precise work to meet all technical requirements while ensuring ease of maintenance. The system was delivered with high assembly quality and full consideration of the project’s spatial and operational constraints.

Our Partners

Let’s Talk!

Got a project in mind? We’d love to hear about it! Fill out the form, and our team will reach out to discuss your requirements, timeline, and next steps. Let’s build something great together!

Or, are you interested in joining our team? We’re always looking for skilled professionals — please navigate to hiring form the using the arrows bellow.